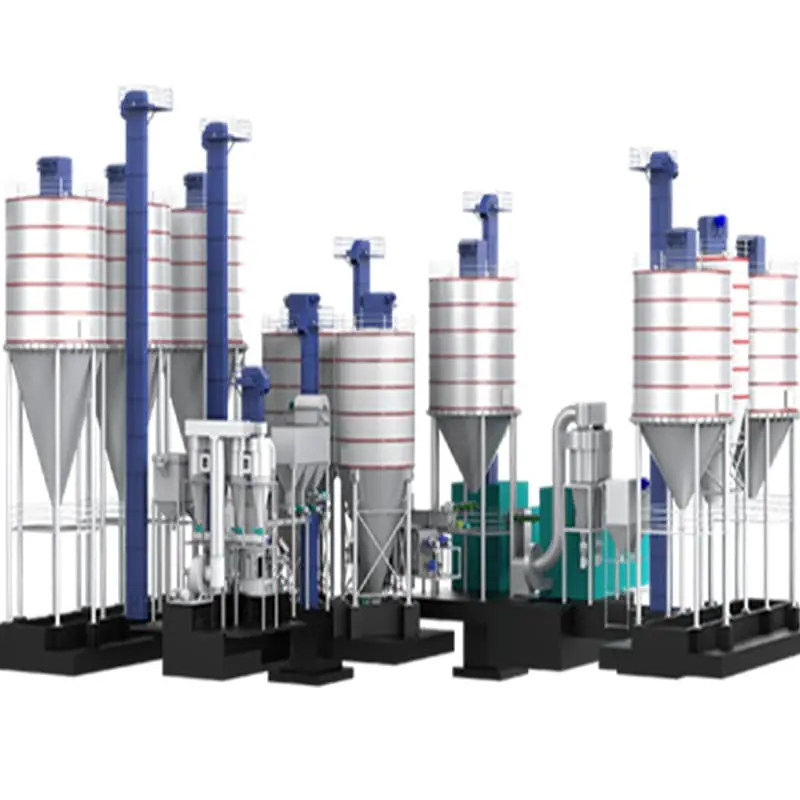

Grinding equipments are widely used in the grinding and processing of materials in fields such as metallurgy, building materials, chemicals, and mining. According to the fineness of the materials to be ground and the fineness of the discharged materials, the grinding equipment can be divided into types such as Raymond grinding mills,Calcium hydroxide production lines and Superfine grinding mills.

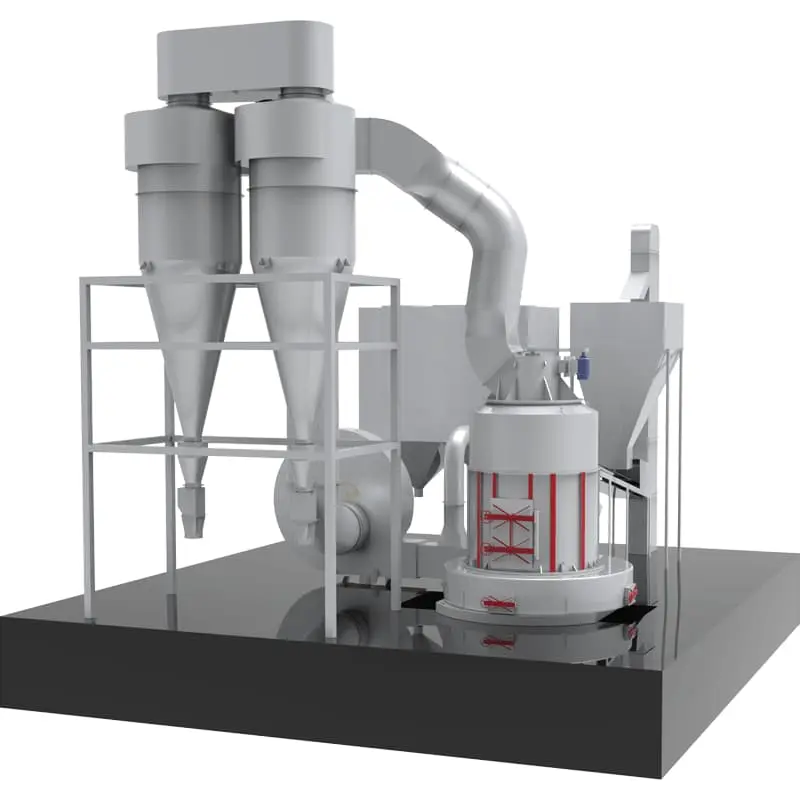

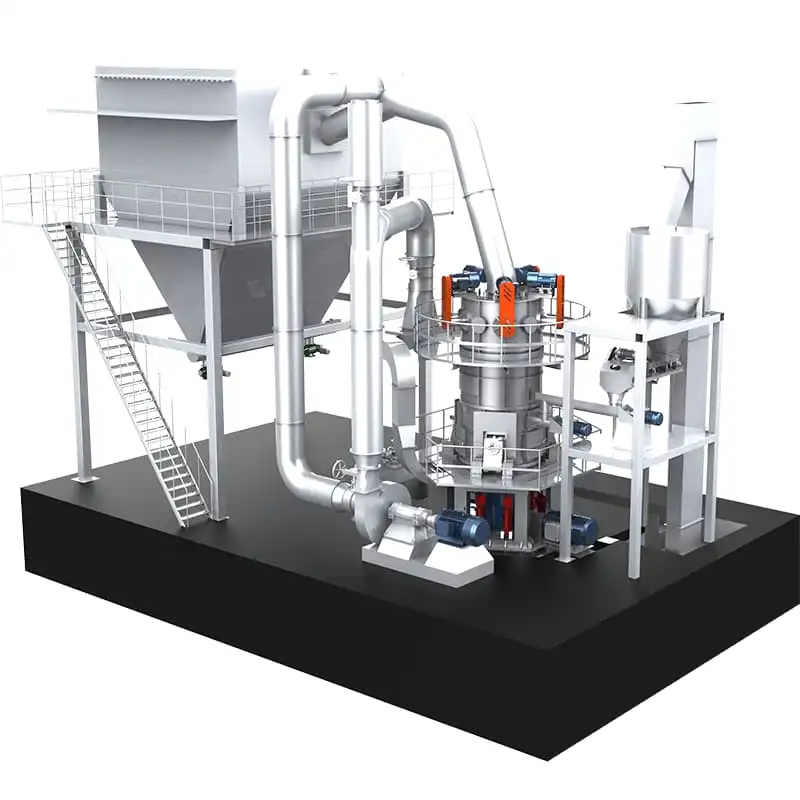

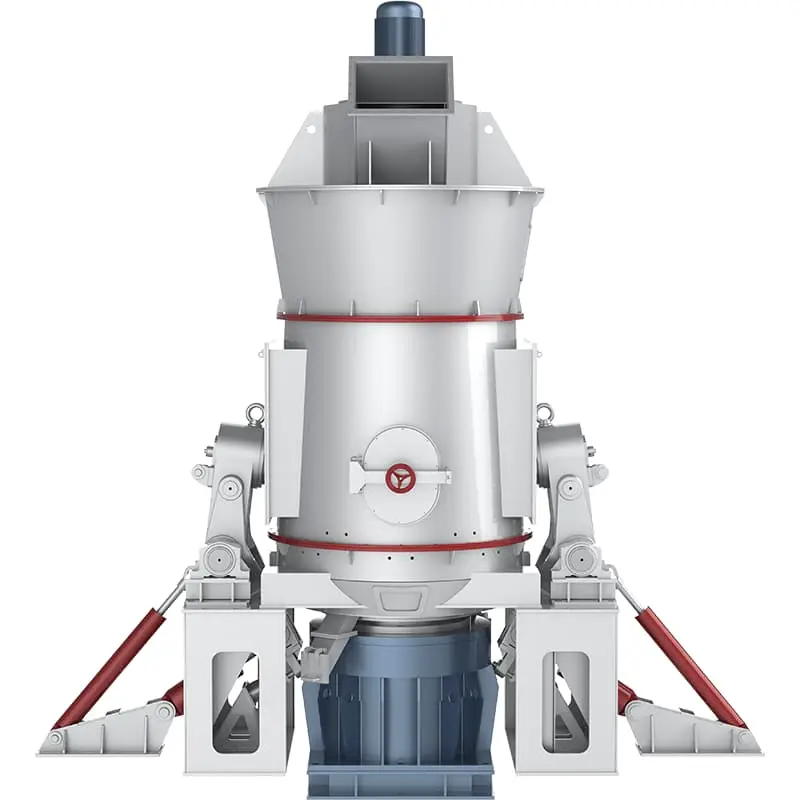

- Raymond Mill

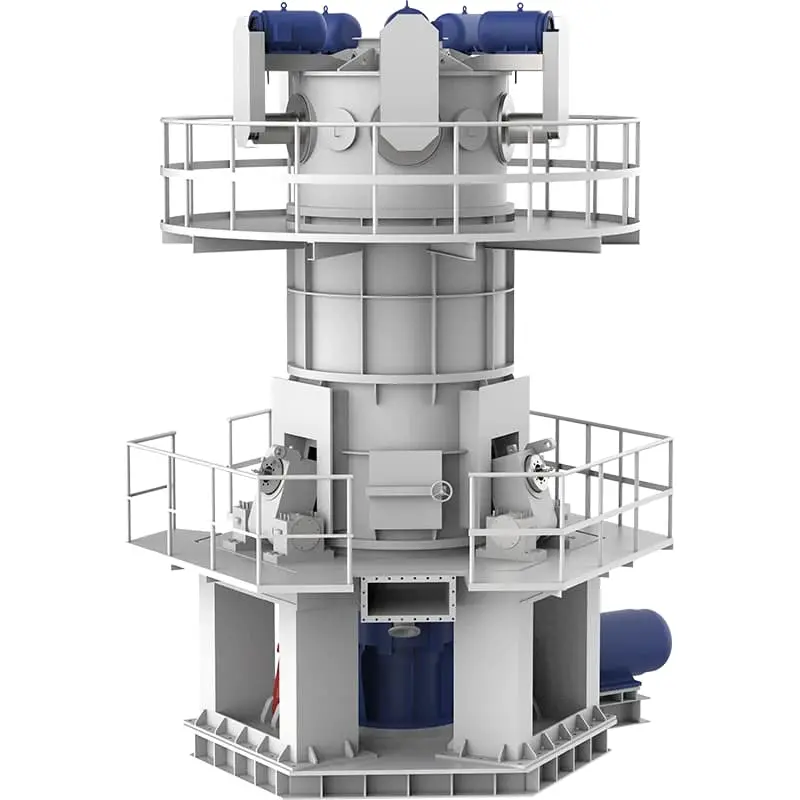

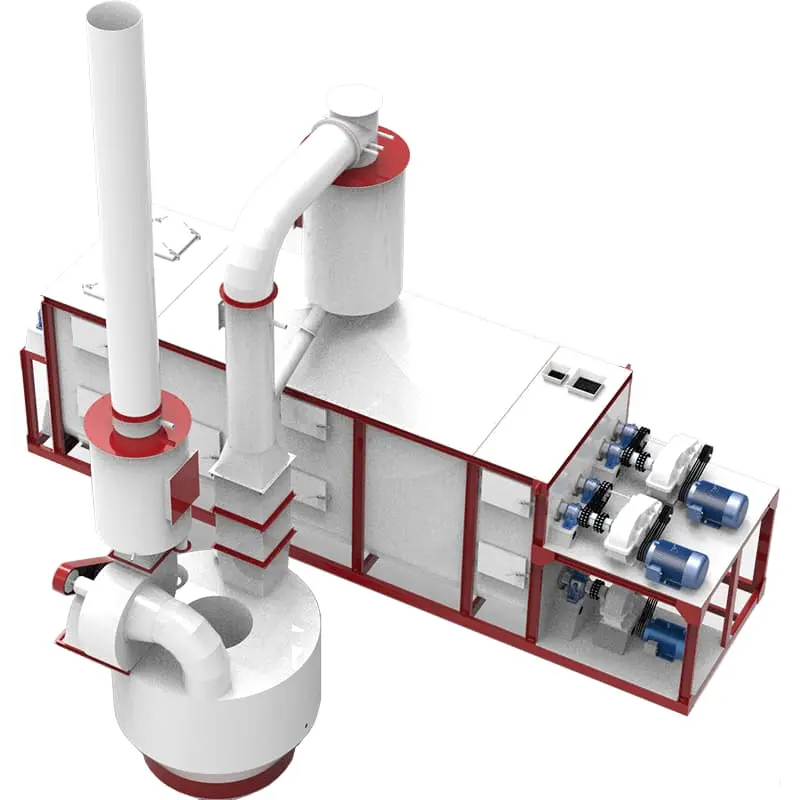

- Superfine Grinding Mill

- Calcium Hydroxide Production Line

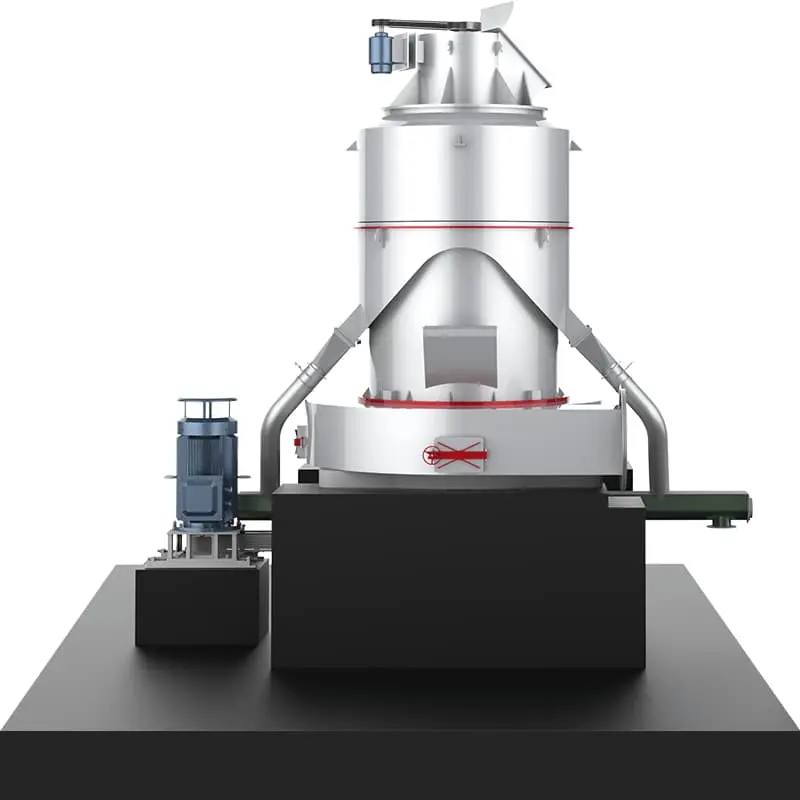

What is a Raymond Mill ?

Raymond grinding mill is a common industrial grinding equipment, mainly used for the grinding and processing of non-metallic ores.

-

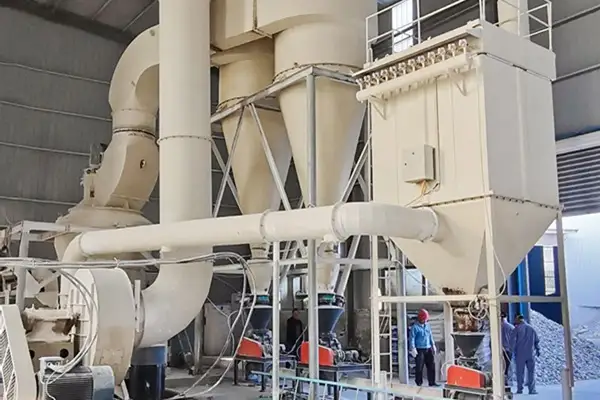

Application scope of Raymond Mill

Raymond grinding mill is suitable for processing non-flammable and non-explosive ores with Mohs hardness below 7 and humidity less than 8%, such as limestone, marble, calcite, potassium feldspar, barite, dolomite, medical stone, granite, bentonite, kaolin, bauxite, gypsum, talc, fluorite, coal cinder, iron oxide red, iron ore, etc., all of which can be efficiently grinding.

-

Working principle of Raymond Mill

The raw materials are coarsely crushed to ≤35 mm by the crusher, and then fed into the main unit of the Raymond grinding mill by the feeder. The grinding rollers are pressed tightly against the grinding ring by centrifugal force to grind the materials. After grinding, the powder is carried to the classifier by the air flow. The coarse particles are reground, and the qualified fine powder is sent to the collection system through the classifier.

-

Core advantages of Cronus Raymond Mill

The Cronus Raymond grinding mill is highly efficient and energy - saving. Its energy utilization rate is higher than that of the ball mill, and energy consumption is reduced by 30% to 40%. The fineness of the finished product can be precisely controlled, and powders with a fineness of 40 to 400 mesh can be produced. The passing rate of 325 - mesh powder is ≥90%, and the particles are uniform. The equipment has a compact structure, is durable, and occupies a relatively small area. Key components are made of high - manganese steel or alloy steel, resulting in a low failure rate.

Cronus has been specializing in manufacturing grinding equipments for 50 years

Shanghai Cronus Machinery Co., Ltd. is a wholly-owned subsidiary of Guilin Mining Machinery Co., Ltd. Guilin Mining Machinery Co., Ltd. was founded in 1973 and is mainly engaged in the design, development and manufacture of various grinding equipments such as Raymond grinding mills,Calcium hydroxide production lines,Superfine grinding mills,etc...

- 1973 year

establish

- 10000 piece

annual output

- 60+ item

technical patents

- 30+ class

Application fields

向下滚动页面显示"置顶"按钮...